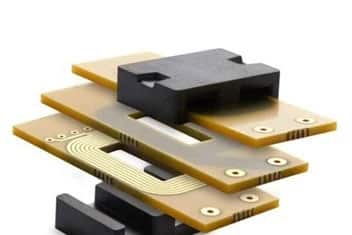

This article written by Pablo Blázquez, Frenetic Power Εlectronics Εngineer discuss the HF Planar Magnetics advantages, challenges, best design practices, ideal applications, and reasons why it’s a game-changer in modern electronics.

High-Frequency Planar Magnetics

High-Frequency Planar Magnetics represents a great technological advance in the world of Electronics.

They are magnetic components specifically designed to operate at high frequencies, typically ranging from hundreds of kilohertz to several megahertz. HFPM comes with a unique set of characteristics that sets it apart from traditional Magnetics, making it a vital component in today’s electronic landscape.

What are the benefits?

HFPM brings an array of benefits to the table, making it a highly desirable choice for different applications. Let’s explore some of these advantages:

- Compact and Lightweight: High-frequency operation allows HFPM to be remarkably smaller and lighter than their low-frequency counterparts. This advantage is a game-changer for applications with limited space or weight constraints.

- Enhanced Efficiency: HFPM exhibits reduced energy losses when compared to low-frequency components. This translates to improved overall efficiency in power conversion systems, which is particularly valuable in energy-conscious industries.

- Minimal Electromagnetic Interference (EMI): Operating at high frequencies inherently results in less electromagnetic interference (EMI). As a result, HFPM is an ideal choice for applications where minimizing EMI is essential, such as medical devices, aviation, and communication equipment.

- Fast Response Time: HFPM offers swift response to changes in input voltage or load conditions. This rapid adjustment capability is invaluable in applications requiring real-time and precise power delivery.

Challenges of High-Frequency Planar Magnetics

While HFPM has numerous advantages, it also presents some unique challenges that engineers must address:

- Skin Effect: At high frequencies, electrical currents tend to concentrate near the surface of conductors. This phenomenon, known as the skin effect, can increase resistance and reduce the efficiency of HFPM components. Proper design techniques are necessary to mitigate this effect.

- Material Selection: Selecting the appropriate core material for HFPM is crucial. Conventional magnetic materials may not perform optimally at high frequencies, necessitating the use of specialized materials with low core loss and high permeability.

- Parasitic Effects: HFPM components are prone to parasitic capacitance and inductance effects, which can impact their performance. Engineers must carefully consider and mitigate these effects during the design phase.

- Heat Management: High-frequency operation can generate more heat in magnetic components. Effective heat dissipation mechanisms must be integrated into the design to ensure reliability.

The Best Design Practices

Now that we’ve explored the benefits and challenges, we can discuss the best practices for designing HFPM. Let’s start with the Skin Effect Mitigation: engineers can employ techniques such as litz wire or foil conductors to minimize the skin effect and ensure optimal current distribution. The material selection is also crucial, and a careful consideration of core materials is essential. Engineers should opt for materials specifically designed for high-frequency applications, ensuring minimal core loss and high permeability.

Parasitic effects reduction needs to be mentioned as well: engineers should employ layout and component placement strategies to minimize parasitic capacitance and inductance. Proper grounding and shielding can also help reduce unwanted effects.

And finally, the Heat control, as an effective heat management is critical for HFPM components. Engineers should integrate heat sinks, thermal vias, and other cooling solutions to prevent overheating and ensure long-term reliability.

Where to Use High-Frequency Planar Magnetics and Why

HFPM components find their best use in various applications across different industries. First, there’s Power Electronics, where HFPM is a cornerstone in compact, high-efficiency power conversion systems, including DC-DC converters, voltage regulators, and high-frequency power supplies. Its efficiency benefits are crucial in conserving energy and reducing waste heat.

Then, there’s Telecommunications, as the fast response time and reduced EMI of HFPM make it an ideal choice for telecommunications equipment, ensuring reliable and efficient power delivery. We need to also mention Aerospace and Avionics, where HFPM helps minimize interference while providing compact and lightweight solutions in EMI-sensitive environments, like aircraft and satellites.

Medical Devices is another field where High-Frequency Planar Magnetics are highly employed. HFPM’s compact size and EMI reduction are crucial in medical equipment, where reliability, space constraints, and low EMI are paramount. And finally, Data Centers, where high-frequency power supplies benefit from HFPM’s compactness and efficiency, ensuring stable power delivery in data centers and server farms.

Conclusion

In conclusion, High-Frequency Planar Magnetics is a transformative technology that offers significant advantages while presenting unique challenges. By adhering to best design practices and leveraging the benefits of HFPM, engineers can unlock their potential in a wide range of applications, from power electronics to telecommunications and beyond.

If you’re exploring the integration of HFPM in your projects or have specific questions, feel free to reach out to us. We’re here to help you unlock the full potential of this game-changing technology!

Read the original post at High-Frequency Planar Magnetics